Blog

Solid State Relay

Introduction

A Solid State Relay (SSR) is an electronic switching device that serves a similar function to an electromechanical relay. SSRs differ significantly in their design and operation.

SSRs do not have any moving parts such as contacts, armatures, or springs. Instead, they rely on solid-state electronics. When an external voltage (AC or DC) is applied across its control terminals, an SSR can switch on or off. This switching action occurs without any physical movement.

Due to the absence of moving components, SSRs have a longer operational lifetime compared to electromechanical relays.

SSRs can be designed to switch AC or DC loads. They use power semiconductor devices like thyristors and transistors to handle currents up to around a hundred amperes.

SSRs switch rapidly compared to electromechanical relays, and

Remember that SSRs are commonly used in applications where reliability, speed, and durability are essential, especially in situations where mechanical relays may fail due to wear and tear.

Table of Contents

Types of SSRs

There are some of the common types of SSRs:

• Control Signal:

DC-to-AC SSR Relay: These SSRs switch AC loads using a low-voltage DC control signal. They are commonly used for applications like lighting control and motor drives.

AC-to-AC SSR Relay: Designed to control AC loads, these SSRs are useful for applications such as heating elements and industrial machinery.

DC-to-DC SSR Relay: Suitable for controlling DC loads, they utilize semiconductor switches like MOSFETs.

DC-to-AC/DC SSR Relay: These versatile relays can handle both AC and DC loads.

• Switching Property:

Instant ON SSR Relay: These SSRs switch on immediately when the control signal is applied.

Zero Switching SSR Relay: Designed to minimize electrical noise, these SSRs turn on when the AC waveform crosses the zero-voltage point.

Peak Switching SSR Relay: These SSRs switch at the peak of the AC waveform.

Analog Switching SSR Relay: Used for precise control, they allow gradual switching.

Advantages of SSRs:

No Moving Parts:

SSRs don’t have any mechanical contacts or moving parts, which means they are not susceptible to wear and tear that can degrade over time. These moving components contributes to SSRs’ longer operational lifespan.

Faster Switching Speeds:

SSRs can switch on and off much faster than electromechanical relays. Their response time is typically in microseconds, making them suitable for applications requiring rapid switching.

Silent Operation:

Since SSRs lack mechanical contacts, they operate silently. There are no audible clicks or vibrations during switching. This feature is advantageous in noise-sensitive environments or when avoiding disturbances is essential.

High Reliability:

SSRs are highly reliable due to their solid-state design. They are less prone to failure caused by mechanical fatigue or contact welding. Traditional relays may suffer from contact bounce or sticking, leading to unreliable switching.

No Arcing or Sparks:

Electromechanical relays generate arcs and sparks when their contacts open or close. These phenomena can cause electrical noise and wear down the contacts. SSRs do not produce arcs because they use semiconductor devices for switching.

Low Power Consumption:

SSRs consume minimal power during operation. Their control input requires only a small current to activate the switching device. Traditional relays, especially those with large coils, draw more power during activation.

Isolation and Safety:

SSRs provide optical isolation between the control circuit and the load circuit. There is no direct electrical connection. This isolation enhances safety, especially in applications where galvanic separation is crucial (e.g., medical equipment, industrial control).

Compact Size and Lightweight:

SSRs are compact and lightweight due to their solid-state construction. They occupy less space on circuit boards or within enclosures. Traditional relays, with their bulky coils and mechanical components, are comparatively larger.

Wide Operating Temperature Range:

SSRs can operate over a broad temperature range without affecting their performance. Traditional relays may exhibit temperature-dependent behavior due to mechanical expansion and contraction.

SSRs find widespread use in various industries and applications some of them as following:

1. Industrial Automation:

SSRs are extensively used in automated manufacturing processes for controlling heaters, motors, and other machinery. They provide reliable switching without mechanical wear, making them ideal for industrial automation.

2. Temperature Control:

In applications like ovens, incubators, and HVAC systems, SSRs are used for precise temperature control. Their fast response time ensures accurate temperature regulation.

3. Heating Systems:

SSRs are widely employed in heating systems for various purposes, also allow high-precision, high-frequency temperature control for these applications:

- Commercial food processing machines

- Plastic injection molding / extrusion

- Furnaces

- HVAC systems

- Textile industry

- Residential heating

- Infrared heating

- Drying processes

- Thermoforming

- Soldering equipment

4. Motor Control:

When it comes to motor control, SSRs play a crucial role and handle inductive loads associated with electric motors: - Pumps

- Compressors

- Conveyor systems

- Fans

- Elevators

- Lifts

- Hoists

5. Medical Equipment:

SSRs are utilized in numerous medical applications. Controlling motors in hospital beds, examination tables, and rehabilitation equipment. Heating controls in sterilization equipment, blood warming units, and incubators.

6. Air Conditioning and Heating Systems:

SSRs are widely used in the heating and cooling systems of Air conditioners, Electric ovens Industrial heaters or furnaces.

They can handle high voltages while remaining compact in size.

Select the Right SSR

Selecting the right Solid State Relay (SSR) for your specific application involves considering several factors such as:

Load Type:

Determine whether your load is AC or DC. Choose an SSR compatible with your load type.

Load Current and Voltage:

Identify the maximum current and voltage your load requires. Select an SSR with a current rating that exceeds your load’s maximum current. Ensure the SSR’s voltage rating matches or exceeds your load voltage.

Switching Frequency:

Consider how often you need to switch the load on and off. Some SSRs are designed for high-frequency switching, while others are better suited for occasional use.

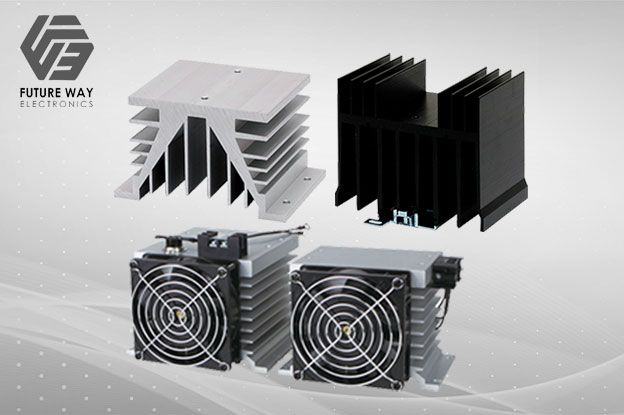

Heat Dissipation and Cooling:

SSRs generate heat during operation. Evaluate whether your application requires additional heat sinks or cooling mechanisms. Check the SSR’s datasheet for thermal specifications.

Transient Voltage Protection:

Assess whether your application is exposed to voltage spikes or surges. Look for SSRs with built-in transient voltage protection.

Zero-Crossing or Instant-On:

Zero-crossing SSRs switch when the AC waveform crosses zero voltage. They minimize electrical noise. Instant-on SSRs switch immediately, suitable for resistive loads.

Form Factor and Mounting:

Consider the physical space available for the SSR. Choose the appropriate package (e.g., panel mount, DIN rail, or PCB mount).

Reliability and Longevity

Check the SSR’s expected lifespan (usually specified in cycles). Some SSRs are rated for harsh environments or outdoor use. Consider the reliability of the manufacturer and the quality of components.

Cost

Balance performance and features with your budget. SSRs vary in price based on specifications.

Remember to consult the SSR’s datasheet, seek expert advice if needed, and test the selected SSR in your specific application before full deployment.