Blog

Instrumentation & Process control

1.1 Instrumentation

Instrumentation & Process control – Instrumentation is the foundation for process control in automation industry. However, it comes in many forms from domestic water heaters and HVAC (Heating Ventilating and Air Conditioning), where the variable temperature is measured and used to control gas, oil, or electricity flow to the water heater, or heating system, or electricity to the compressor for refrigeration, to complex industrial process control applications such as used in the petroleum or chemical industry. In industrial control a wide number of variables, from temperature, flow, and pressure to time and distance, can be sensed simultaneously. All of these can be interdependent variables in a single process requiring complex microprocessor systems for total control. Due to the rapid advances in manufacturing technology of instruments, in use today may be obsolete tomorrow, as new and more efficient measurement techniques are constantly being introduced. These changes are being driven by the need for higher accuracy, quality, precision, and performance. To measure parameters accurately, techniques have been developed that were thought impossible only a few years ago.

1.2 Process Control

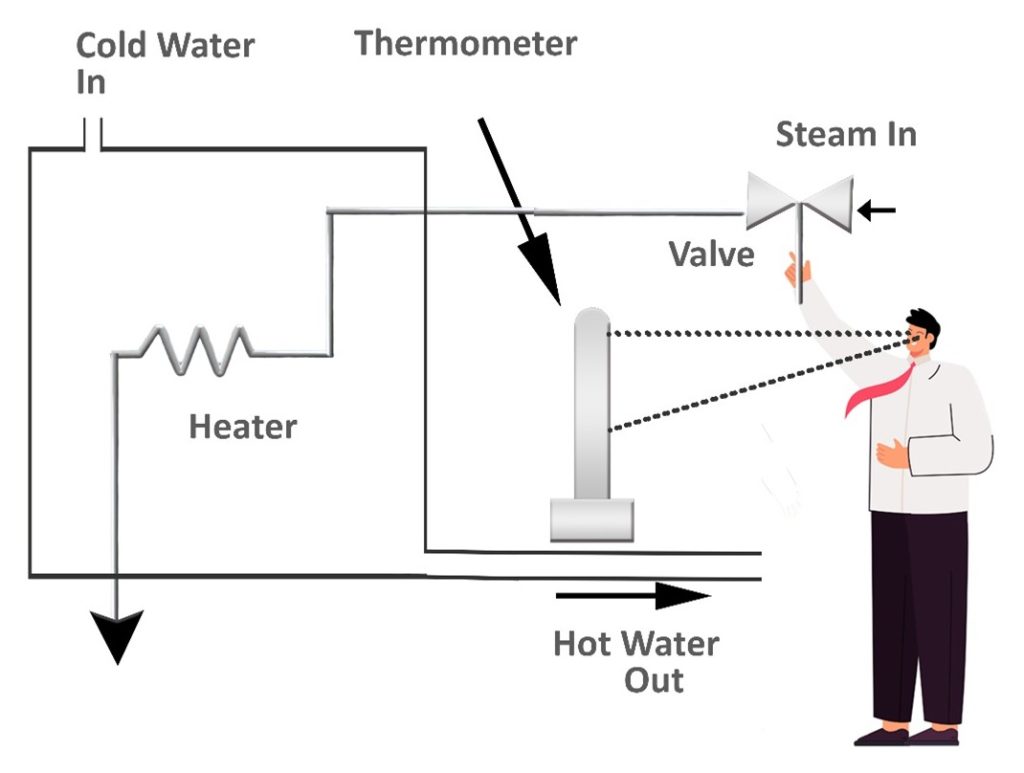

In order to produce a product with consistently high quality, tight process control is necessary. A simple-to-understand example of process control would be the supply of water to a number of cleaning stations, where the water temperature needs to be kept constant in spite of the demand. A simple control block is shown in Fig. 1.2a. Steam and cold water are fed into a heat exchanger, where heat from the steam is used to bring the cold water to the required working temperature.

Figur1.2a: The manual control of a simple heat exchanger process loop

A thermometer is used to measure the temperature of the water (the measured variable) from the process or exchanger. The temperature is observed by an operator who adjusts the flow of steam (the manipulated variable) into the heat exchanger to keep the water flowing from the heat exchanger at the constant set temperature. This operation is referred to as process control, and in practice would be automated as shown in Fig. 1.2b.

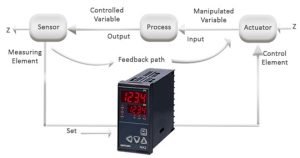

Figure1.2b: The automatic control of a heat exchanger processor loop “Digital temperature controller NX9-model” (www.fweuae.com)

Process control is the automatic control of an output variable by sensing the amplitude of the output parameter from the process and comparing it to the desired or set level and feeding an error signal back to control an input variable in this case steam. See Fig. 1.2b. A temperature sensor attached to the outlet pipe senses the temperature of the water flowing. As the demand for hot water increases or decreases, a change in the water temperature is sensed and converted to an electrical signal, amplified, and sent to a controller that evaluates the signal and sends a correction signal to an actuator. The actuator adjusts the flow of steam to the heat exchanger to keep the temperature of the water at its predetermined value.

Figure 1.2c: Block diagram of a process control loop “Digital temperature controller NX2-model” (www.fweuae.com)

The diagram in Fig. 1.2a/b is an oversimplified feedback loop and is expanded in Fig. 1.2c In any process there are a number of inputs, from chemicals to solid goods. These are manipulated in the process and a new chemical or component emerges at the output. The controlled inputs to the process and the measured output parameters from the process are called variables. In a process-control facility the controller is not necessarily limited to one variable, but can measure and control many variables.

Witten by: Zahra Faramarzi (Email:faramarz_zhr@yahoo.com)